As the number of installed solar projects continues to climb, and projects installed in the late 1990s and early 2000s approach the end of their usable life, there is mounting concern over what happens to used solar panels after they are decommissioned. Are they left to rot? Sent to a landfill? Or are they recycled responsibly?

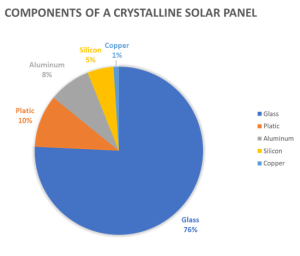

Before we dive into the current process and opportunities for improvement, it’s important to first understand the core materials involved. A typical crystalline silicon solar panel is made primarily of glass (75% by weight), plastic (10%), aluminum (8%), silicon (5%), and copper (1%.) The remaining 1% is composed of a variety of metals, primarily used in solder.

Before we dive into the current process and opportunities for improvement, it’s important to first understand the core materials involved. A typical crystalline silicon solar panel is made primarily of glass (75% by weight), plastic (10%), aluminum (8%), silicon (5%), and copper (1%.) The remaining 1% is composed of a variety of metals, primarily used in solder.

Glass, representing the bulk of the material used in solar panels, as well as aluminum, both can be melted and recycled into new products with no loss in material quality. In fact, because both materials retain their integrity after recycling, products made using recycled glass and aluminum can be recycled repeatedly. Because of this “infinite recyclability,” they are ideal recycling materials, and are both commonly recycled already.

Plastic, making up roughly 10% of the panels, can be a bit more problematic. Plastic is inexpensive to produce, and while some types of plastic are commonly recycled, the durable acrylic plastics used in solar panels are more difficult and expensive to recycle. There are, however, specialized facilities that can and do break down these materials for future use. As the volume of solar panels approaching end-of-life increases, more and more of these facilities are opening, gradually reducing the cost to recycle these materials.

Finally, both silicon and copper are high-quality and high-cost materials. Processing the silicon wafers to prepare them for recycling can be a difficult task, requiring advanced machinery and high temperatures. But again, as the demand, and potential for profit, increases, the number of facilities capable of breaking down solar panels continues to increase.

Because solar electric technologies were adopted earlier and more widely in Europe as compared to the United States, the European solar recycling infrastructure is more mature and able to handle a greater load. The Waste Electrical and Electronic Equipment Directive of the European Union helped found a member-based organization called PV Cycle to build that recycling infrastructure. That same organization is currently helping to build the required recycling infrastructure in the US, so that the industry can continue to meet the increasing demand.

See one of PV Cycle’s Recycling Plants in Action:

https://youtu.be/81-MEpcA-Rc

https://youtu.be/81-MEpcA-Rc

Want to learn more? Check out these sources, which were referenced in this article:

https://polychem-usa.com/acrylic-recycling/

https://pv-magazine-usa.com/2020/05/27/solar-panel-recycling-turning-ticking-time-bombs-into-opportunities/

https://www.greentechrenewables.com/article/can-solar-panels-be-recycled

https://www.aluminum.org/industries/production/recycling

https://www.acplasticsinc.com/informationcenter/r/solar-energy-plastic